150 years ago, Amsterdam was a smelly city. Household waste was collected, but often ended up in the canal or the gutter. This changed after the Dienst Stadsreiniging, a service dedicated to keeping the city clean, was established in 1877. To show you how far we have come, here is a brief overview of our rich history:

From landfill to incineration

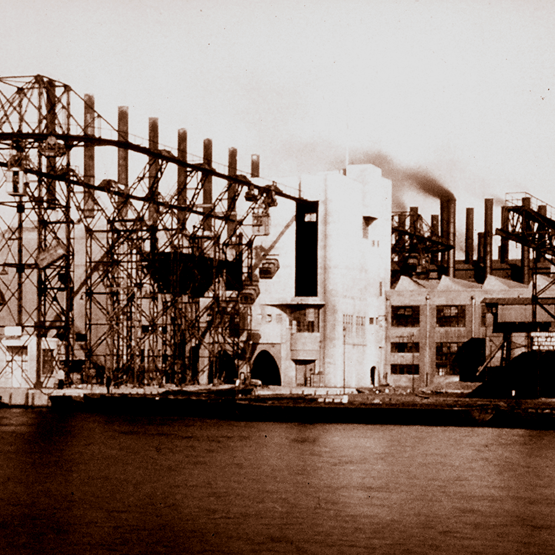

In our early days, all waste was landfilled, but the old rubbish dumps and landfill sites were a major nuisance to the city’s residents. In the early 20th century, the city council’s decision to dump the waste in the Naardermeer lake instead was met with heavy protests. The city council gave in, deciding instead to build a waste incineration plant in Amsterdam-Noord in 1913. The eight furnaces were first fired in 1918, after which barges would bring in large quantities of waste through the canals for incineration.

Waste-to-energy plant in Amsterdam-Noord

Nearly half a century later, environmental requirements had been tightened and the incineration plant had become unable to cope with the massive increase in waste. The old plant was demolished and a waste processing plant was built in Amsterdam-Noord in 1969. This plant was twice the size of its predecessor, as well as being considerably more efficient and environmentally friendly. For the first time ever, flue emissions were treated with an electrofilter.

Waste-to-energy plant in Westpoort

Prompted by the need for expansion, the city council decided in 1987 to build a third-generation waste incineration plant in Amsterdam-Westpoort: the Waste-to-Energy plant (W2E), marking a tremendous leap in terms of capacity, technology and sustainability. It was the first plant to meet the new emission requirements by effectively eliminating the emission of dioxins and other harmful substances. This facility was completed and commissioned in 1993.

High-Efficiency Power Plant

When it became clear that greater incineration capacity was needed, the city also decided to build a fourth-generation waste incineration plant: the High-Efficiency (HE) power plant, which was completed in 2007. The HE power plant was equipped with state-of-the-art technology, including several proprietary innovations created in the W2E plant. Thanks to these innovations, including an advanced reheating system, the electrical HE power plant has reached an efficiency level of 30%. The combined processing capacity of the W2E and HE plants are 1,400,000 tons of waste per year.

AEB corporatised

In the year that construction began on the HE power plant, the Gemeentelijke Dienst Afvalwerking (Municipal Waste Management Service) changed its name to Afval Energie Bedrijf (Waste-to-Energy Company) to highlight all the energy it generated by incinerating waste. On January 1, 2014, the company was corporatised and renamed AEB Amsterdam, with the City of Amsterdam as its sole shareholder. The organization will continue as AEB Amsterdam from that date on.

Separation plant

Moving toward a sustainable, circular society means recovering as many raw materials as possible from waste. In 2017, AEB built a modern separation plant to do just that, separating metals, plastics and paper from household waste in order to contribute to an optimally circular society in which raw materials are reused where possible and residual waste is used to generate heat and electricity.